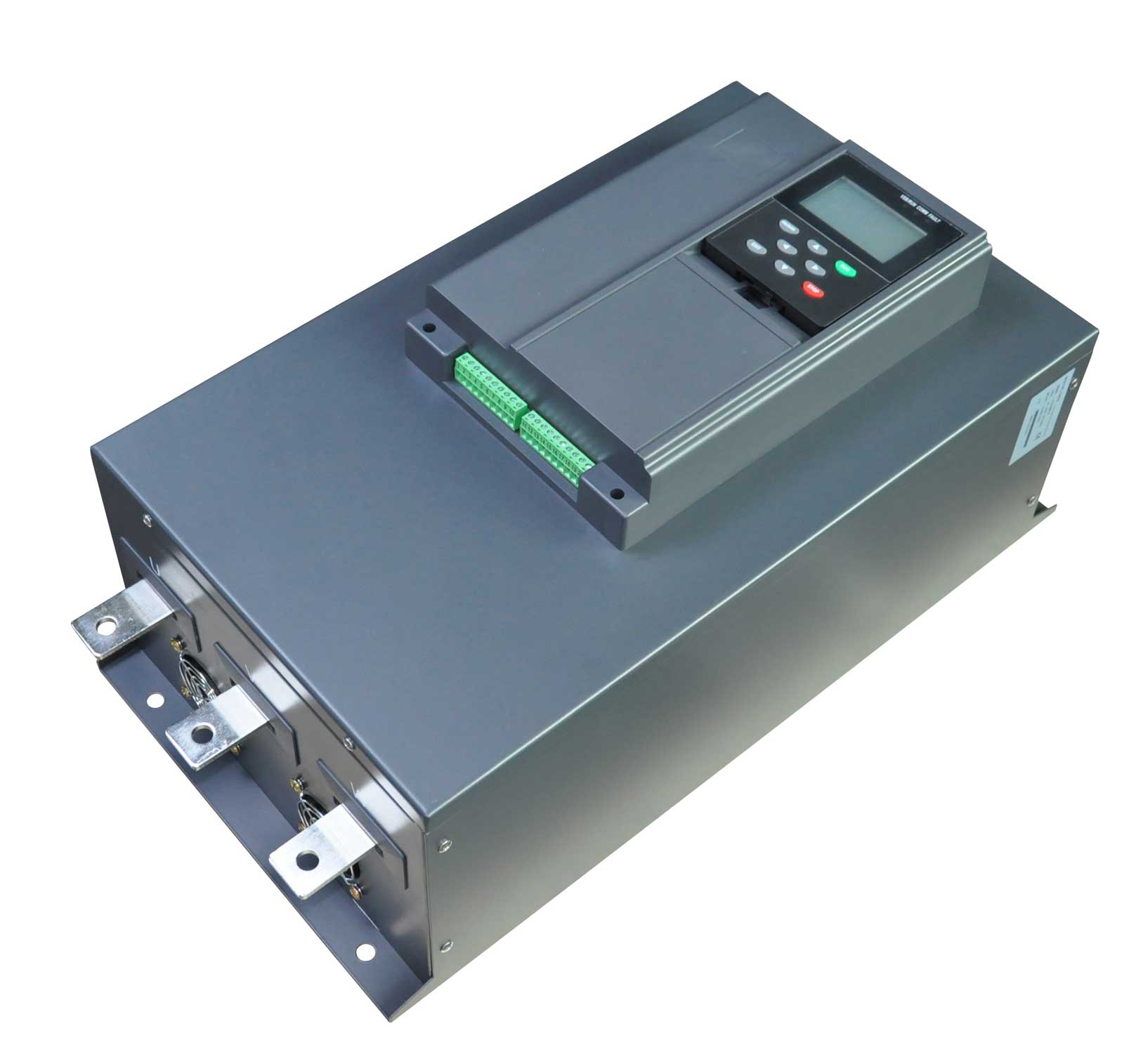

FST-860 Elevator dedicated frequency converter all-in-one machine

FST-860 series is an integrated elevator controller that integrates computer technology, automatic control technology, network communication technology, and motor vector drive technology. This series of controllers adopts a brand new structural design, with overall aesthetics, reasonable layout, and more clean and environmentally friendly materials used; Safe, reliable, and energy-saving, providing customers with comprehensive elevator solutions that meet the new national standards.

Power range

3.7kw~30KG

Input voltage

Three phase 380V input and three phase 380V output

Product Overview

-

Elevator mini icon

-

Elevator mini icon

-

Elevator mini icon

-

Packaging

-

Food

-

Fans

-

Pumps

- Integrated control and drive, compact structure, simple operation;

- Strong environmental adaptability, achieving self-learning of weighing at any weight;

- Multiple security protection, in accordance with GB/T7588.1/2020 standard;

- Dual chip control operation and holding brake function;

- High performance vector control, economical and easy to use, improves the safety and stability of elevators;

- The perfect combination of CANbus and Modbus communication;

- Flexible and rich modular value-added accessories.

Technical Specifications

| Items | Specifications | ||

| General Specifications | Carrier frequency | 0.5k〜16k(Hz);The carrier frequency is automatically adjusted according to the load characteristics. | |

| Input frequency resolution | Digital setting: 0.01Hz | ||

| Analog setting: Maximum frequency *0.1% | |||

| Output frequency accuracy | Digit setting: Maximum frequency x±0.01% | ||

| Analog setting: Maximum frequency *±0.01% | |||

| Control mode | Open loop vector control (SVC)/ Closed loop vector control (VC)/VF control | ||

| Starting torque | 0.5HZ/180% (SVC); 0Hz/200% (VC) | ||

| Speed range | 1:100 (SVC) | 1:1000 (VC) | |

| Speed stability accuracy | ±0.5% (SVC) | ±0.05% (VC) | |

| Overload capacity | 150% rated current 60 seconds; 180% rated current for 1 second. | ||

| Acceleration and deceleration curve | Linear or S-curve acceleration and deceleration mode; Four groups of acceleration and deceleration time and four groups of S-curve setting; Multiple combinations | ||

| Overhaul control | Can be specified by any multi-segment speed | ||

| Multi-speed operation | Achieve up to 8 speed runs | ||

| Automatic Voltage Regulation (AVR) | When the grid voltage changes, it can automatically keep the output voltage constant | ||

| Display and operation | LED display | The parameter of setting frequency, output frequency, output voltage and output current can be displayed | |

| LCD Displays the operation panel | Select accessories, Chinese or English prompt operation content | ||

| Parameter copy | The LCD operating panel allows for fast replication of parameters | ||

| Protection function | 40 kinds of protection such as power-on short circuit detection, input-output phase loss protection, overcurrent protection, overvoltage protection, undervoltage protection | ||

| Key lock and function selection | Lock part or all of the keys and define the scope of some keys to prevent misoperation | ||

| Own Features | Power on the safety self-test of peripheral devices | It can realize the safety detection of peripheral devices such as grounding and short circuit | |

| Power failure emergency operation | The emergency operation scheme is simple and convenient | ||

| Overspeed protection | Built-in elevator overspeed protection function; Multiple action options | ||

| Judging velocity deviation | Built-in speed deviation detection function; Timely detection of potential elevator hazards | ||

| Strong urgent function | It has the function of forced speed change detection; Effectively prevent the elevator from hitting the top and squatting the bottom | ||

| Motor temperature detection | Determine the motor temperature in time to eliminate safety hazards | ||

| Starting compensation | Two starting torque compensation methods; Analog or digital quantities | ||

| QUICK key | The user can freely define the shortcut menu | ||

| Timing control | Convenient timing control function | ||

| Input-output characteristic | Run command channel | Three channels: operation panel given, control terminal given, communication given | |

| Frequency source | There are five frequency sources: digital set, analog voltage set, analog current set, communication set, multi-speed set | ||

| Input terminal | 10 digital input terminals, lifting 1 can be used as high-speed pulse input, can be compatible with active PNP or NPN input mode | ||

| Three analog input terminals, one of which can only be used as voltage input, and the other one can be used as voltage or current input | |||

| Output terminal | Three digital output terminals | ||

| 2 relay output terminals | |||

| 2 analog output terminals, respectively optional 0/4~20mA or 0/2~10V, can achieve the set frequency, output frequency and other non-power output | |||

| Environment | Altitude | Area 1000 m | |

| Ambient temperature | -10 ° C ~40 ° C (ambient temperature is 40 ° C ~50 ° C, please use the reduced rate) | ||

| Humidness | Less than 95%RH, no boiling condensation | ||

| Vibration | Less than 5.9 m/s ² (0.6g) | ||

| Storage temperature | -20℃~60℃ | ||

Product Parameters

| Model no. | Power | output current | Input voltage | Size(mm) | Installation size(mm) | G.W |

| FST-860-5R5GT4 | 5.5KW | 13A | 380V | 200*276*140 | 147*267 | 5.12KG |

| FST-860-7R5GT4 | 7.5KW | 18A | 380V | 225*350*185 | 150*335 | 6.54KG |

| FST-860-11GT4 | 11KW | 27A | 380V | 225*350*185 | 150*335 | 6.54KG |

| FST-860-15GT4 | 15KW | 33A | 380V | 225*350*185 | 150*335 | 6.54KG |

Download

Download  Contact Us

Contact Us