News

Site Editor

Site

https://anyhz.usa18.wondercdn.com/uploads/image/653decbc2fb16.png

An edge banding machine, as the name suggests, is a common piece of equipment used for edge banding in woodworking machinery. Suitable for straight edge sealing and trimming of medium-density fiberboard, blockboard, solid wood board, particle board, polymer door panel, plywood, etc. It can be equipped with double-sided adhesive edge sealing, cutting edge sealing, adhesive pressing, trimming, chamfering, rough trimming, fine trimming, scraping, and polishing functions at once. Due to its delicate edge sealing, lubrication, and good hand feel, the sealing line is flat and lubricated. The equipment operates stably and reliably, making it particularly suitable for manufacturers of panel furniture such as furniture and cabinets.

Site

https://anyhz.usa18.wondercdn.com/uploads/image/653decbc2fb16.png

An edge banding machine, as the name suggests, is a common piece of equipment used for edge banding in woodworking machinery. Suitable for straight edge sealing and trimming of medium-density fiberboard, blockboard, solid wood board, particle board, polymer door panel, plywood, etc. It can be equipped with double-sided adhesive edge sealing, cutting edge sealing, adhesive pressing, trimming, chamfering, rough trimming, fine trimming, scraping, and polishing functions at once. Due to its delicate edge sealing, lubrication, and good hand feel, the sealing line is flat and lubricated. The equipment operates stably and reliably, making it particularly suitable for manufacturers of panel furniture such as furniture and cabinets.

Application of central air conditioning frequency converter

Views: 228

Author: Site Editor

Publish Time: 2023-11-22

Origin: Site

Introduction:

Central air conditioning is one of the indispensable supporting facilities for large supermarkets, hotels, office buildings, etc. According to statistics, electricity consumption accounts for about 50% of the total building consumption. The central air conditioning system is designed with a maximum load and an additional margin of 10% to 20%. Due to changes in season, day and night, and user load, the actual load is much smaller than the design load, with a full load operation time of less than 1%. Although the load of the central air conditioning refrigeration unit can automatically adjust the load with seasonal temperature changes, the refrigeration pump, cooling pump, and cooling tower fan matched with the system cannot automatically adjust the load, Long term operation at 100% load results in significant energy waste and significant energy-saving potential.

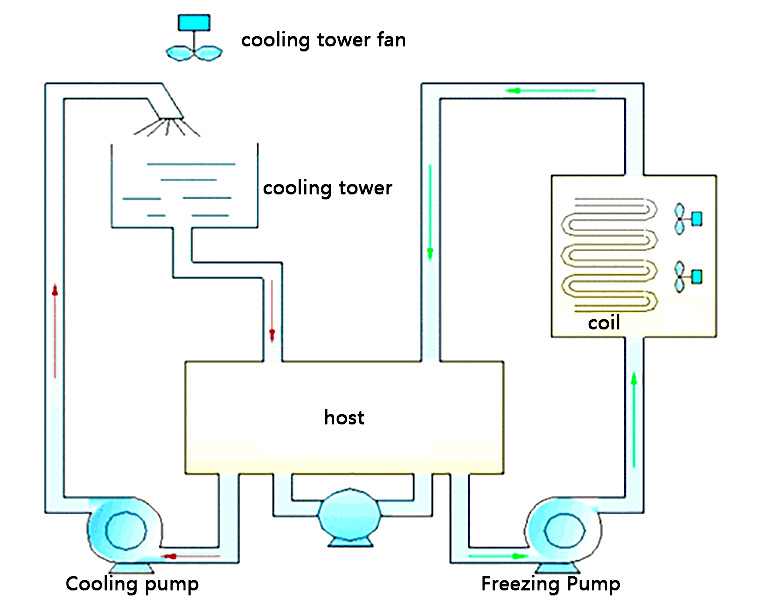

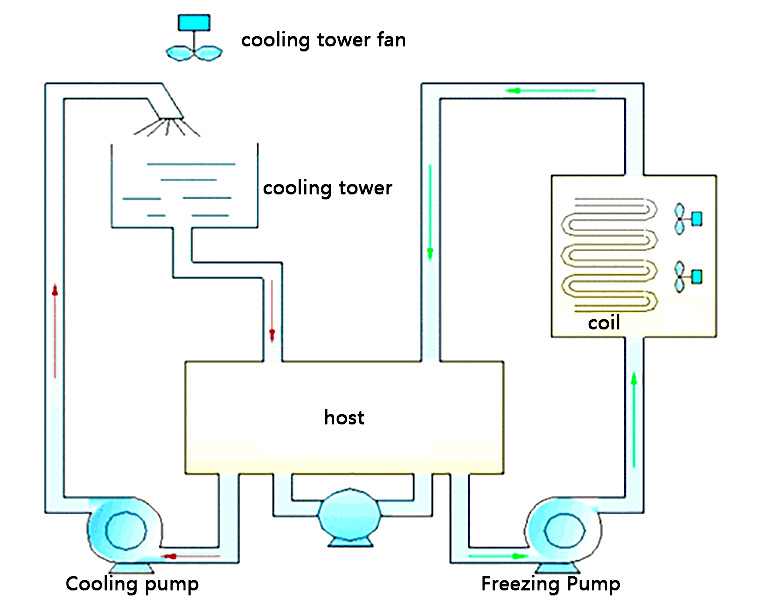

Typical composition of central air conditioning system:

Chilled water circulation system

This section mainly consists of chilled water pumps, terminal fan panels, cabinets, and chilled water pipelines. The low-temperature chilled water flowing out of the main evaporator is pressurized by a refrigeration pump and sent into the chilled water pipeline, where it enters the room for heat exchange, taking away the heat in the room, and finally returning to the main evaporator. Indoor fan panel cabinet is used to blow air through the chilled water pipeline, reduce air temperature, and accelerate indoor heat exchange.

Cooling water circulation system

This section consists of a cooling pump, cooling water pipeline, and cooling water tower. The chilled water circulation system, while conducting indoor heat exchange, will inevitably take away a large amount of indoor heat energy. This heat energy is transferred to the cooling water through the refrigerant inside the host, causing the temperature of the cooling water to rise. The cooling pump will feed the heated cooling water pressure into the cooling water tower, allowing it to exchange heat with the atmosphere.

Refrigeration host

The main unit of the central air conditioning system consists of a refrigeration compressor, evaporator, condenser, throttle valve, and refrigerant. Its working cycle process is as follows: first, the low-temperature and low-pressure gaseous refrigerant is pressurized by the compressor into a high-temperature and high-pressure liquid, which enters the condenser and is cooled by cooling circulating water. Then, the heat is released into the atmosphere through an outdoor cooling tower. Subsequently, it is throttled and depressurized by a throttle valve to become a low-pressure gas-liquid mixture that enters the evaporator. The refrigerant continuously vaporizes in the evaporator, while absorbing heat from the chilled circulating water to form cold water. Finally, the vaporized refrigerant in the evaporator turns back into low-pressure gas and enters the compressor again, repeating this cycle.

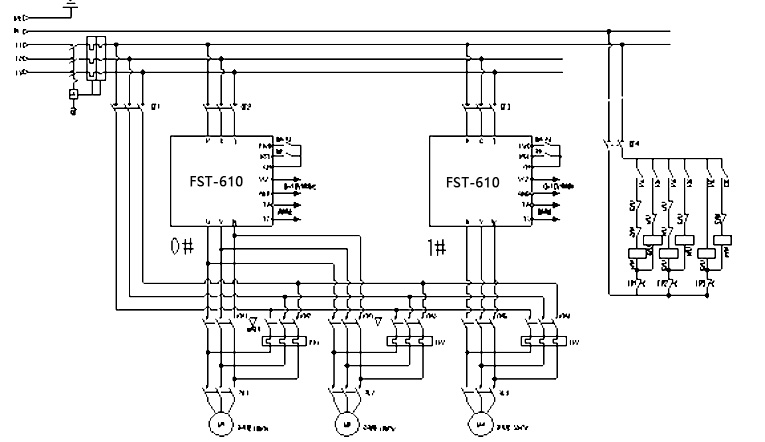

Central air conditioning renovation plan

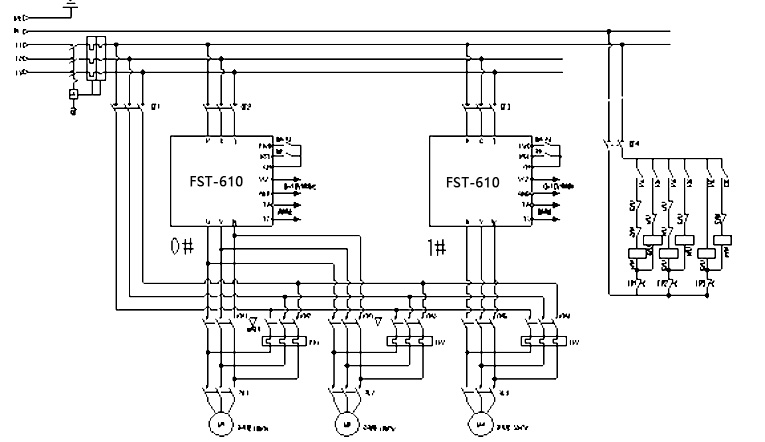

1. Control scheme for circulating water system

The chilled water circulation system adopts parameters such as stable temperature difference (adjusting the output frequency of the frequency converter in real-time according to the cooling amount to stabilize the temperature difference) and pressure difference (ensuring that the pressure at the highest cooling point meets the requirements) for control; The cooling water circulation system adopts stable temperature difference and environmental temperature and humidity control of the cooling tower. The temperature difference and environmental temperature and humidity control of the cooling system are significantly better than the control of the outlet temperature of the cooling water. Control the temperature difference between the inlet and outlet of the chilled and cooling water at 4.5-5 ℃. The control system forms a closed-loop control system through PID adjustment and frequency converter based on the feedback signal of load changes. The PLC controls the frequency of frequency converter operation and the number of water pumps based on monitoring values, thereby adjusting the circulating water flow and controlling the speed of heat exchange in the central air conditioning system.

2. Control scheme for cooling tower cooling system

The temperature sensor of the cooling tower cooling system detects the outlet water temperature value of the cooling tower, controls the outlet water temperature of the cooling tower to 27~29 ℃, and the PLC controls the number of cooling tower fans and the frequency of frequency converter operation based on the outlet water temperature to achieve the set value of the outlet water temperature of the cooling tower.

The advantages of frequency conversion transformation in central air conditioning systems

1. Adopting closed-loop control with frequency converter, software configuration can be carried out as needed and temperature can be set for PID adjustment, so that the output power of the motor varies with the change of thermal load, achieving maximum energy saving while meeting usage requirements;

2. The frequency converter has a soft start and stop function, which reduces vibration, noise, and wear, prolongs equipment maintenance cycle and service life, reduces impact on the power grid, and improves system reliability;

3. The frequency converter has multiple protective measures for the motor, such as overvoltage, undervoltage, overcurrent, and grounding, greatly improving the operating rate and safety reliability of the system;

4. The isolation effect of the DC capacitor in the frequency converter makes the input power factor close to 1, and the excitation reactive current of the motor is provided by the capacitor, which can save the grid capacity;

5. The closed-loop control system of variable frequency speed regulation is interlocked with the original power frequency control system, which does not affect the operation of the original system. In the event of maintenance or failure of the closed-loop control system of variable frequency speed regulation, the original power frequency control system can still operate normally.

Main debugging matters

1. After the installation of the rectification equipment is completed, first write the programmed program into the PLC, set the frequency converter parameters, inspect the electrical components, and gradually power on and debug them;

2. When putting into trial operation, artificially reduce the load, observe whether the flow rate decreases due to the decrease in frequency, and find the lowest frequency of the frequency converter when the refrigeration machine alarms, as well as the circulation situation at the end of the pipeline after the flow rate decreases, so that the frequency converter works at a stable working point at the lowest point;

3. Use a thermometer to timely detect the temperature at each point, in order to verify the accuracy of the temperature sensor and verify the status of various working conditions.

Conclusion

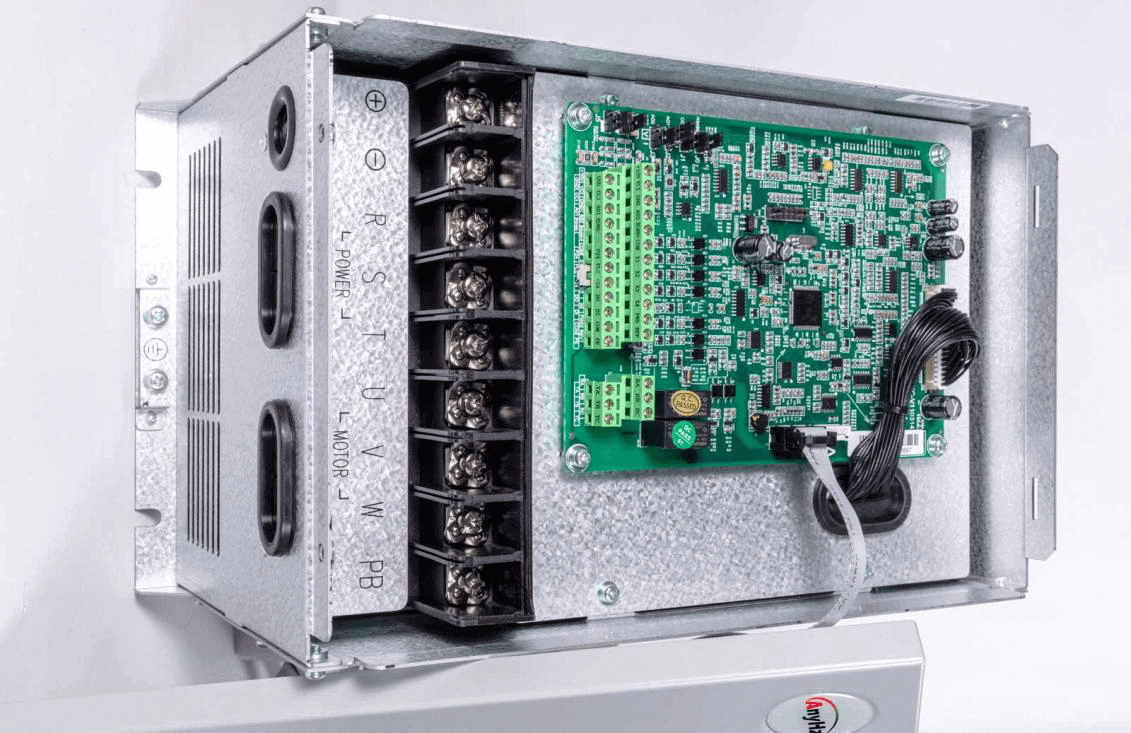

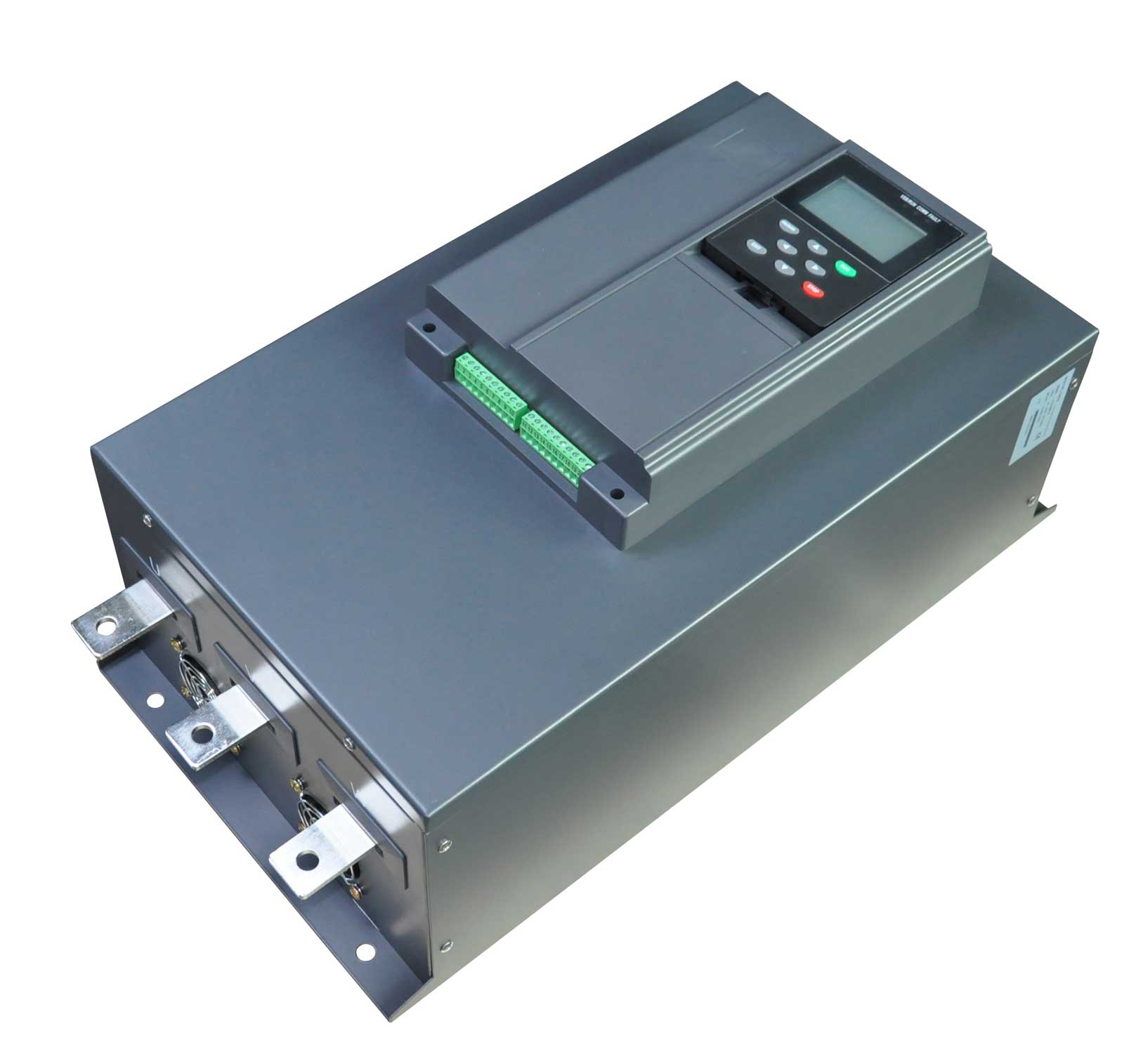

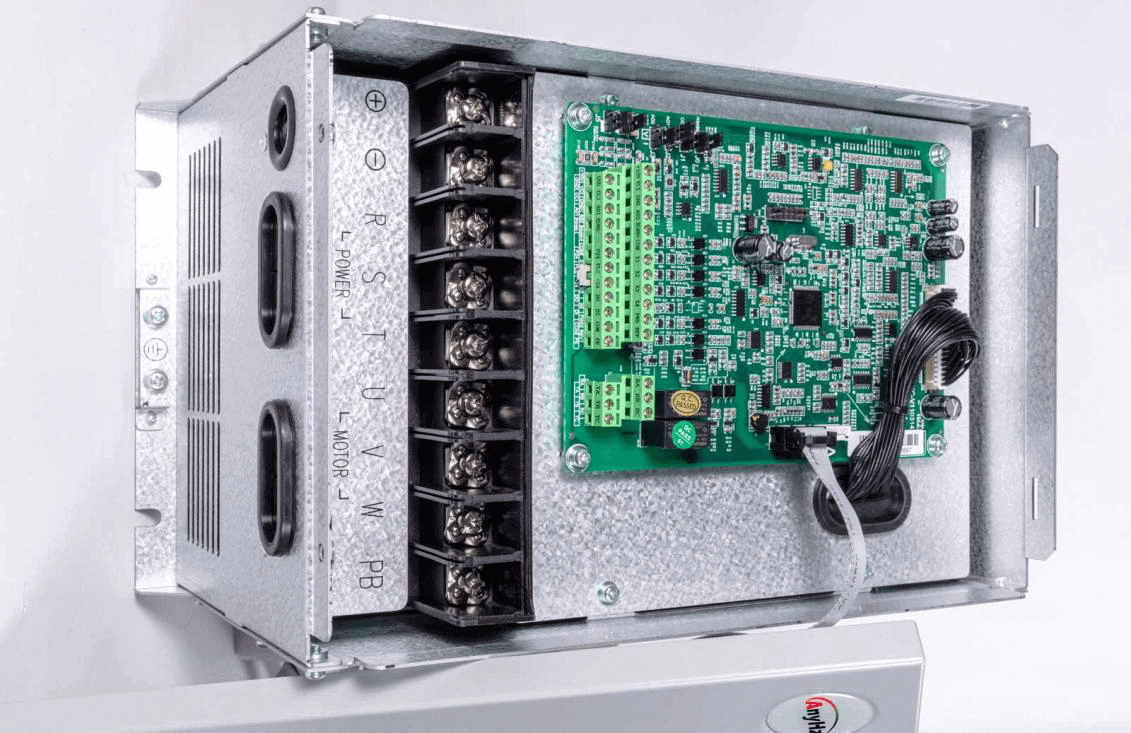

The ANYHZ FST-610 series frequency converter is applied to the central air conditioning system, using a frequency conversion closed-loop control motor to set the temperature as needed, allowing the equipment to reserve capacity and adjust the thermal load over time and seasons through speed regulation, achieving maximum energy savings while meeting usage requirements. At present, it has been successfully applied to multiple energy-saving renovation sites of central air conditioning, and according to statistical analysis, the average energy-saving rate has reached over 30%.

Contact Us

Contact Us