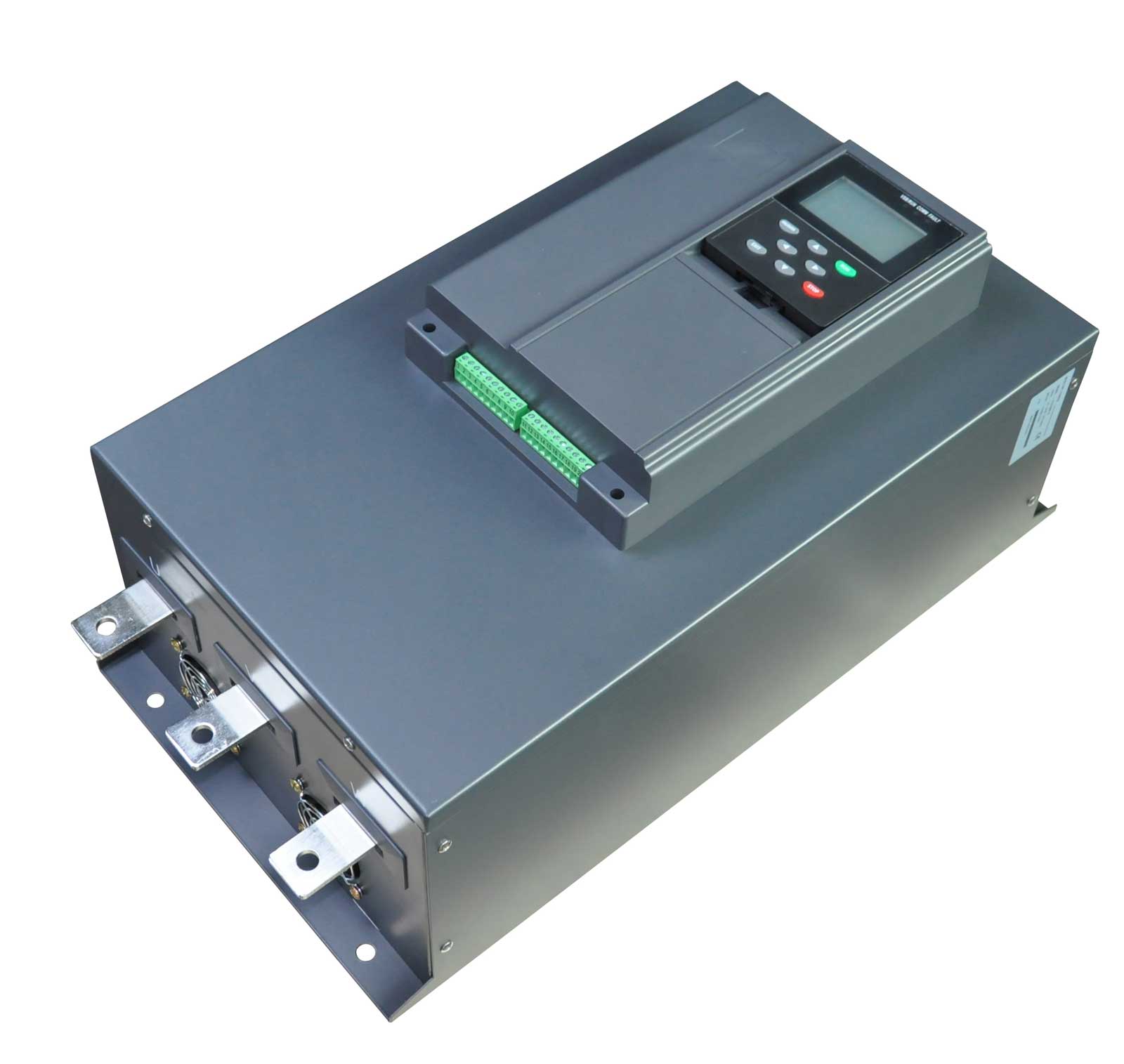

FST-650L-PV Photovoltaic Water Pump Dedicated Frequency Converter

The FST-650L-PV photovoltaic water pump dedicated frequency converter adopts MPPT high-efficiency tracking and intelligent frequency conversion technology, and is tailored for applications such as precision agricultural irrigation, mountain water supply projects, and desert ecological restoration. It achieves seamless coupling between photovoltaic power generation and water pump systems, with industry-leading conversion efficiency, making it an ideal core device for building a green, low-carbon, and smart water management system.

Power range

0.4Kw~500Kw

Input voltage

220V 1 phase to 220V 3 phase

380V 3 phase to 380V 3 phase

Product Overview

Application scope

-

Textile

-

Paper Making

-

Sand Making

-

Machine Tools

-

Packaging

-

Food

-

Fans

-

Pumps

- Advanced MPPT algorithm: Ensures solar power tracking efficiency reaches 99%;

- Easy operation: Simply connect the photovoltaic panel to the frequency converter; no parameters need to be set, and the photovoltaic water pump will start automatically after power-on;

- Comprehensive voltage levels and power range: Supports single-phase 220V, three-phase 220V, and three-phase 380V water pump motors, with power ranging from 0.4kW to 500kW;

- Supports mixed power supply: All products can simultaneously input photovoltaic DC and grid AC, meeting the requirements for 24-hour unattended operation;

- Multiple protection measures: Features PV overvoltage protection, PV reverse polarity alarm, and automatic over-temperature derating protection functions, effectively extending product lifespan.

Technical Specifications

| Iterms | Technical Index | Specification |

| Input | Input voltage |

lΦAC220V±15% 3ΦAC380V± 15% 3ΦAC660V± 15% |

| Input frequency | 47-63Hz | |

| Efficiency | ≥97% | |

| Output | Output voltage | 0- Rated voltage |

| Output frequency | 0-500Hz | |

| Control Features | Control Mode | Speed sensorless vector control,Vector control with speed sensor,V/F control |

| Run Command Mode | Panel control, terminal control, serial communication | |

| Frequency setting method | Digital setting, analog quantity setting, pulse frequency setting, serial communication setting, multi segment speed setting and simple PLC setting, PID setting, etc., can achieve combination and mode switching of given methods | |

| Overload capacity | G type: 150% rated current 60S, 180% rated current 10S | |

| P type: 120% rated current 60S, 150% rated current 10S | ||

| Starting torque | 0.5Hz/180% (SVC) ;1Hz/180% (V/F) | |

| Speed regulation range | 1:100 (SVC) | |

| Speed control accuracy | ± 0.5% maximum speed (SVC) | |

| Carrier wave frequency | 1.0-15.0KHz,Automatically adjustable according to temperature and load characteristics | |

| frequency resolution | Digital setting: 0.01Hz Analog setting: Maximum frequency * 0.1% | |

| Torque increase | Automatic torque increase; Manual torque increase by 0.1% -10.0% | |

| Acceleration and deceleration methods | DC, four types of acceleration and deceleration times | |

| DC braking | DC braking during startup and DC braking during shutdown | |

| Inching operation | Inching operation frequency: 0.0Hz - maximum frequency output, inching plus or minus time 0.1-3600.0S | |

| Simple PLC and multi speed operation | Up to 16 segments of speed operation can be achieved through built-in PLC or control terminals | |

| Built in process PID | A closed-loop control system that facilitates the implementation of process quantities such as pressure, temperature, flow rate, etc | |

| Automatic voltage adjustment | When the voltage of the power grid changes, it can automatically maintain a constant output voltage | |

|

Control function |

Common DC bus | Multiple frequency converters share a DC bus for automatic energy balancing |

| Torque control | No PG torque control | |

| Swing frequency control | Multiple triangular wave frequency control | |

| Counting control | Counting function | |

|

Input/ output terminals |

Input terminal | Programmable Dl: 7 switch inputs, including 1 high-speed pulse input |

| Programmable AI: 2 channels, VCI: voltage -10V~10V; Voltage 0-10V or current 0-20mA input | ||

| Output terminal |

Programmable open collector output: 1 output (open collector output or high-speed pulse output), 2 relay outputs Analog output: 2 outputs, selectable from 0/4-20mA or 0-10V |

|

| Communication terminal | Provide RS485 physical interface and support Modbus RTU communication mode | |

| Interface | LED display | Can display parameters such as frequency, output frequency, output voltage, output current, etc |

Product Parameters

| Model.no | Power | output current | Input voltage | Size(mm) | Installation size(mm) | G.W |

| FST-650L-0R7S2 | 0.75KW | 4A | 220V | 89.7*197*145 | 71.4*184.2 | 1.5KG |

| FST-650L-1R5S2 | 1.5KW | 5A | 220V | 89.7*197*145 | 71.4*184.2 | 1.5KG |

| FST-650L-2R2S2 | 2.2KW | 9A | 220V | 89.7*197*145 | 71.4*184.2 | 1.5KG |

| FST-650L-0R7G/1R5PT4 | 0.75KW/1.5KW | 2.5A/3.7A | 380V | 89.7*197*145 | 71.4*184.2 | 1.5KG |

| FST-650L-1R5G/2R2PT4 | 1.5KW/2.2KW | 3.7A/5A | 380V | 89.7*197*145 | 71.4*184.2 | 1.5KG |

| FST-650L-2R2G/4R0PT4 | 2.2KW/4KW | 5A/9A | 380V | 89.7*197*145 | 71.4*184.2 | 1.5KG |

| FST-650L-4R0G/5R5PT4 | 4KW/5.5KW | 9A/13A | 380V | 89.7*197*145 | 71.4*184.2 | 1.5KG |

| FST-650L-5R5G/7R5PT4 | 5.5KW/7.5KW | 13A/17A | 380V | 102*200*165 | 90*189.8 | 1.9KG |

| FST-650L-7R5G/011PT4 | 7.5KW/11KW | 17A/25A | 380V | 102*200*165 | 90*189.8 | 1.9KG |

| FST-650L-011G/015PT4 | 11KW/15KW | 25A/32A | 380V | 125*240*175 | 108*228 | 3.1KG |

| FST-650L-015G/018PT4 | 15KW/18KW | 32A/37A | 380V | 125*240*175 | 108*228 | 3.1KG |

| FST-650L-018G/022PT4 | 18KW/22KW | 37A/45A | 380V | 210*345*210 | 140*320 | 8.9KG |

| FST-650L-022G/030PT4 | 22KW/30KW | 45A/60A | 380V | 210*345*210 | 140*320 | 9KG |

| FST-650L-030G/037PT4 | 30KW/37KW | 60A/75A | 380V | 210*345*210 | 140*320 | 9.1KG |

| FST-650L-037G/045PT4 | 37KW/45KW | 75A/90A | 380V | 295*525*225 | 160*505 | 19.5KG |

| FST-650L-045G/055PT4 | 45KW/55KW | 90A/110A | 380V | 295*525*225 | 160*505 | 19.6KG |

| FST-650L-055G/075PT4 | 55KW/75KW | 110A/150A | 380V | 295*525*225 | 160*505 | 19.8KG |

| FST-650L-075G/090PT4 | 75KW/90KW | 150A/176A | 380V | 340*580*250 | 200*560 | 29.6KG |

| FST-650L-090G/110PT4 | 90KW/110KW | 176A/210A | 380V | 340*580*250 | 200*560 | 29.8KG |

| FST-650L-110G/132PT4 | 110KW/132KW | 210A/250A | 380V | 400*610*290 | 240*590 | 50.5KG |

| FST-650L-132G/160PT4 | 132KW/160KW | 250A/300A | 380V | 400*610*290 | 240*590 | 51.3KG |

| FST-650L-160G/185PT4 | 160KW/185KW | 300A/340A | 380V | 500*780*350 | 400*760 | 76KG |

| FST-650L-185G/200PT4 | 185KW/200KW | 340A/380A | 380V | 500*780*350 | 400*760 | 77KG |

| FST-650L-200G/220PT4 | 200KW/220KW | 380A/415A | 380V | 500*780*350 | 400*760 | 78.5KG |

| FST-650L-220G/245PT4 | 220KW/245KW | 415A/470A | 380V | 500*780*350 | 400*760 | 79KG |

| FST-650L-245G/280PT4 | 245KW/280KW | 470A/520A | 380V | 750*860*460 | 500*840 | 155KG |

| FST-650L-280G/315PT4 | 280KW/315KW | 520A/600A | 380V | 750*860*460 | 500*840 | 158KG |

| FST-650L-315G/355PT4 | 315KW/355KW | 600A/640A | 380V | 750*860*460 | 500*840 | 159KG |

| FST-650L-355G/400PT4 | 355KW/400KW | 640A/690A | 380V | 750*860*460 | 500*840 | 161KG |

| FST-650L-245G/280PT4C | 245KW/280KW | 470A/520A | 380V | 750*1300*465 | floor type | 199KG |

| FST-650L-280G/315PT4C | 280KW/315KW | 520A/600A | 380V | 750*1300*465 | floor type | 200KG |

| FST-650L-315G/355PT4C | 315KW/355KW | 600A/640A | 380V | 750*1300*465 | floor type | 200KG |

| FST-650L-355G/400PT4C | 355KW/400KW | 640A/690A | 380V | 750*1300*465 | floor type | 202KG |

| FST-650L-400G/450PT4C | 400KW/450KW | 690A/860A | 380V | 950*1500*515 | floor type | 250KG |

| FST-650L-450G/500PT4C | 450KW/500KW | 780A/860A | 380V | 950*1500*515 | floor type | 250KG |

| FST-650L-500G/560PT4C | 500KW/560KW | 860A/950A | 380V | 950*1500*515 | floor type | 250KG |

Download

Download

Contact Us

Contact Us